PROCESS

1.Material Development

We select the most suitable material for the design and handle material development as necessary.

2. Design Development

We select and develop the most suitable materials based on the design concept and needs, and develop designs suitable for collaborations and applications.

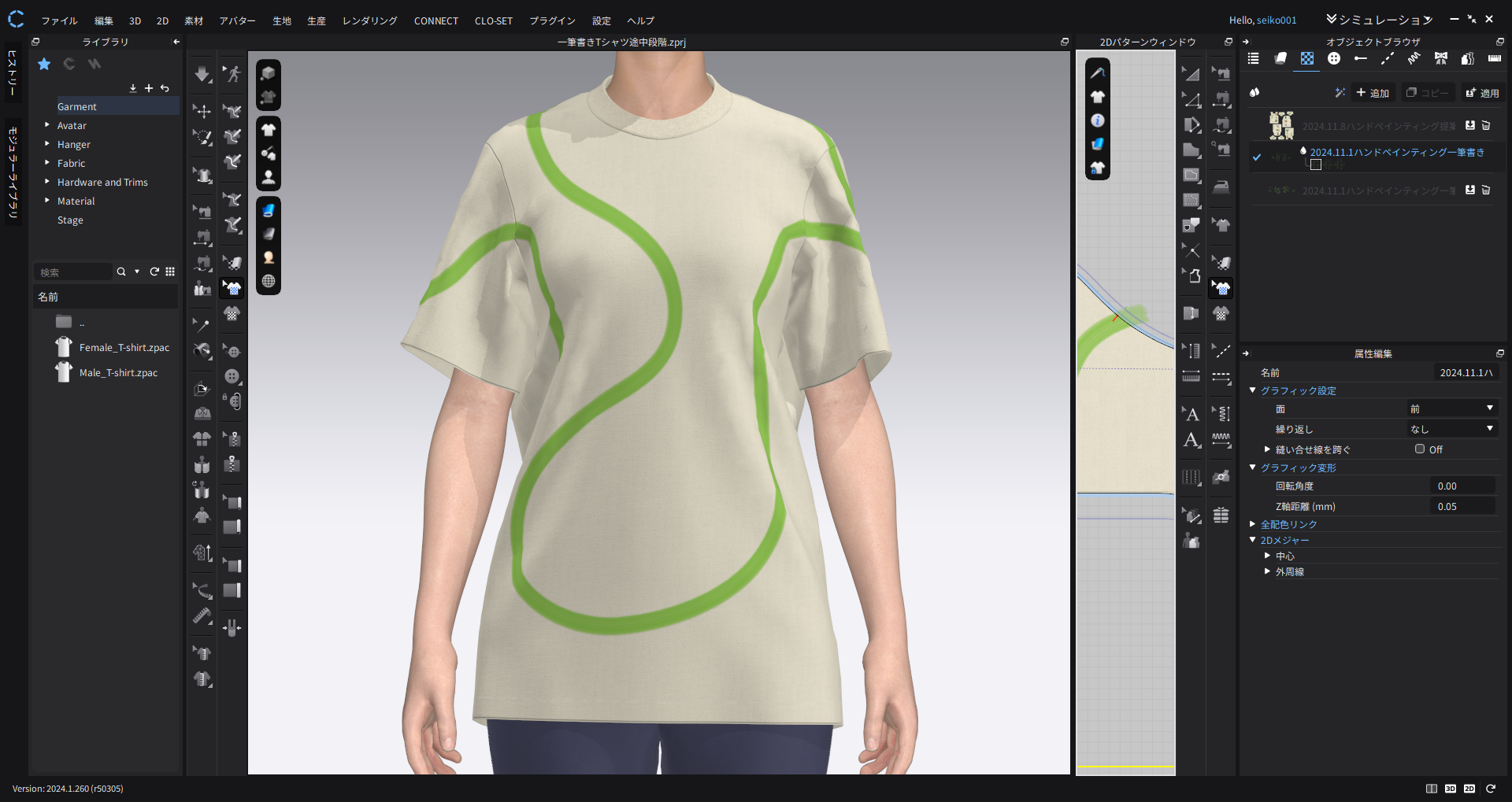

3.3D Graphic Simulation

Design Innovation

From 2D imagination to 3D reality. New discoveries can be made that are unique to three-dimensional objects, enabling more creative manufacturing.

Speed Up

Design visualization accelerates decision making and enables validation without prototyping, shortening development time.

Improved accuracy through data utilization

We use digital data from the planning stage to improve the precision of the final product.

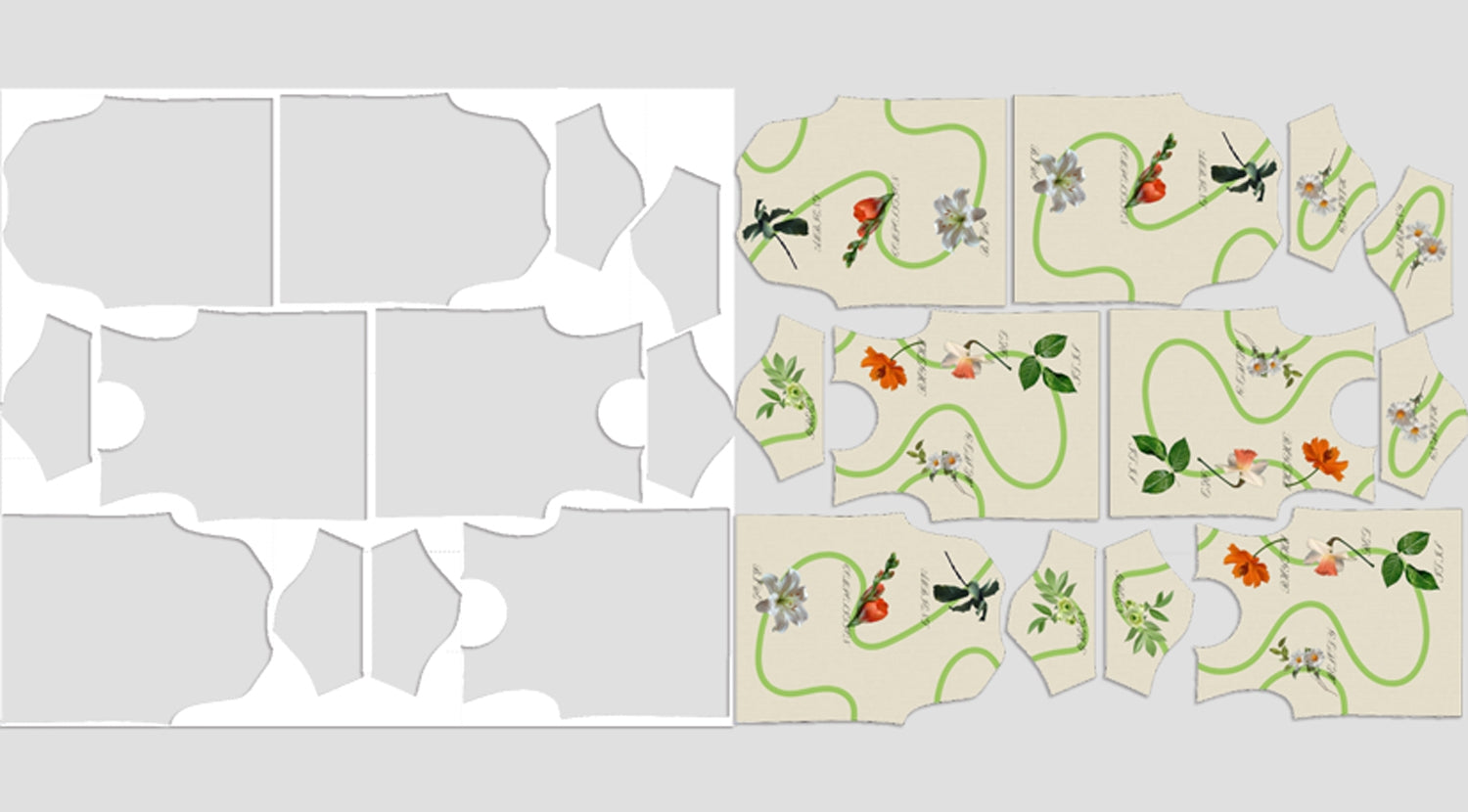

4.2D Graphic Patterns

Development from 3D to 2D

We use our unique know-how to convert simulated 3D graphics into 2D patterns, accurately reproducing the silhouette verified in 3D.

Precise dimensional adjustment through reduction design

Taking into account the finished dimensions, we calculate the shrinkage rate according to the characteristics of the fabric. By optimizing the shrinkage rate design, we achieve the desired size and fit.

Designed with sewing process in mind

Taking into consideration the actual sewing process, we designed the optimal pattern. We created data that is easy to cut and sew, and ensures consistent quality during mass production.

5. Graphic markers

Our proprietary graphic markers minimize fabric waste and reduce costs.

By not printing on scraps, they are easier to recycle and the environmental impact is reduced.

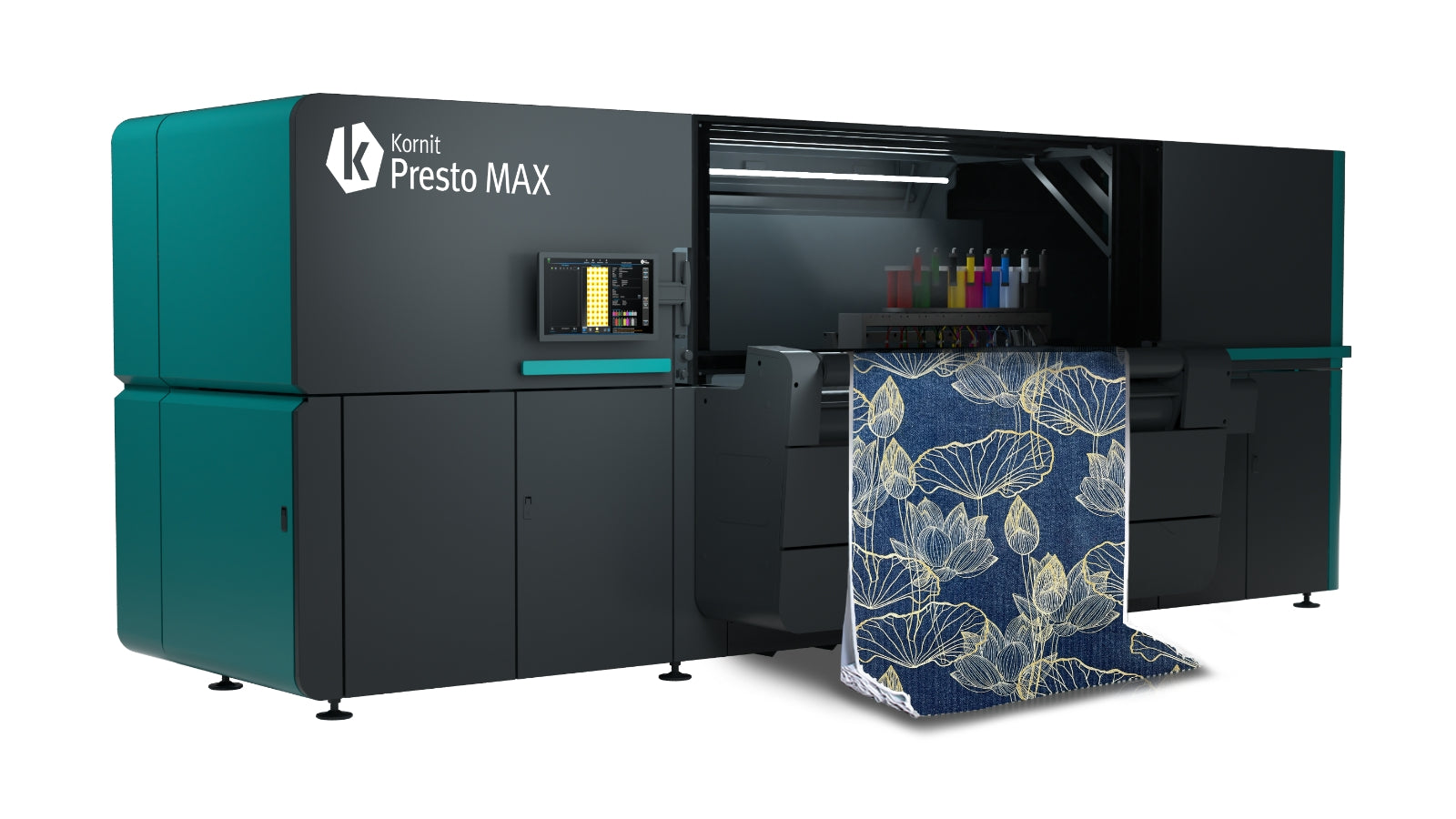

6. Inkjet printing

Since it is compatible with all kinds of fabrics and printing can be done by just one person, it allows for flexible sample, small lot and additional production without extra cost.

7. Toyota Sewing System (TSS)

We are the first Japanese cut and sew manufacturer to introduce the Toyota Sewing System (TSS).

We control materials, planning, patterns, production, and quality control all at our headquarters, and can handle small lots and multiple items.

We are constantly striving to improve quality and efficiency by identifying issues and problems in each process and making repeated improvements.